There is no doubt that the production of spodumene lepidolite vertical mill is increasing in recent years. This is because the mineral has been increasingly used in a variety of industries, particularly in the production of high-quality jewellery and other decorative items.

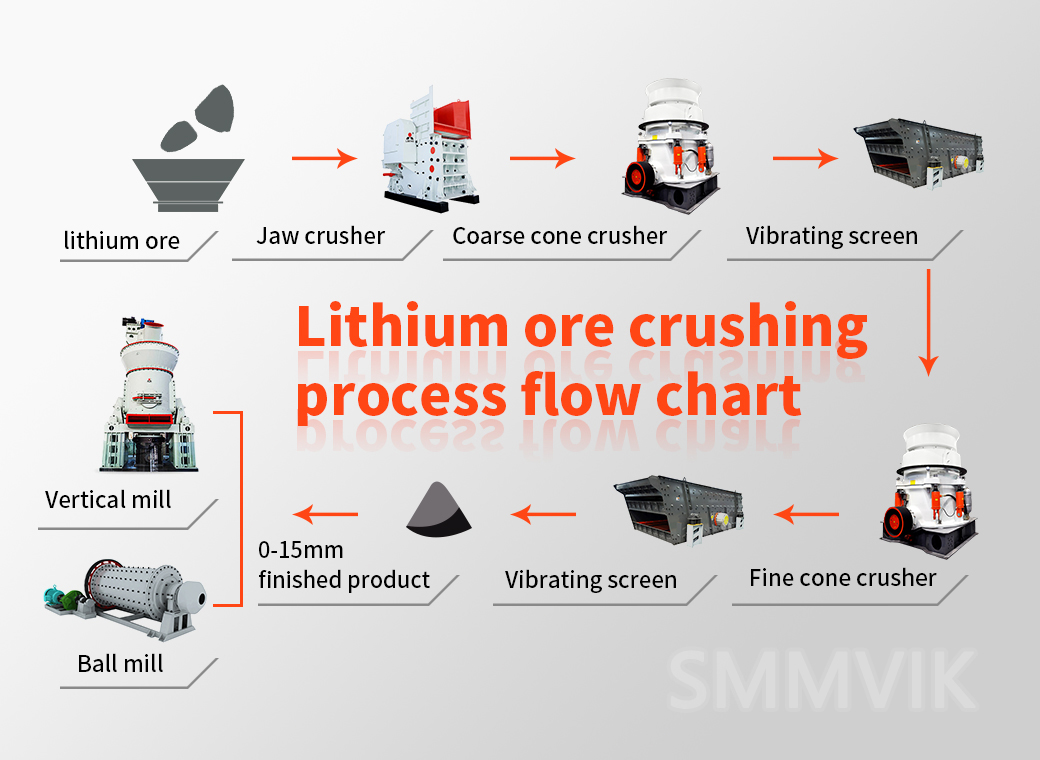

The first step in producing these products is to purchase raw materials. This can either be obtained from mines or produced synthetically. Once this has been done, processing begins by crushing the ore into small pieces. Next, a series of separators are used to remove all impurities, including metallic particles and other minerals. The lepidolite concentrate is then passed through a series of filters to produce a clean product.

The next step is to start rolling the lepidolite pellets using specialist machinery. This involves rotating them at high speeds within a rotating drum or millstone. Doing this results in the pellet becoming smaller and more uniform in shape, as well as increasing its surface area. This increases its ability to absorb heat, which is key for producing high-quality jewellery and other decorative items.

Why choose a spodumene lepidolite vertical mill?

The vertical mills are the most efficient type of crusher and can produce high quality rough or final product. A spodumene lepidolite vertical mill is the most commonly used type of this machine in the world. The following are some of the benefits of using a vertical mill for grinding:

1. High production rate. Vertical mills have a high production rate because they can grind materials quickly and easily.

2. Low startup cost. Vertical mills tend to have a low startup cost because they require little maintenance.

3. Low energy consumption. Vertical mills use less energy than other types of crushers, which makes them environmentally friendly.

4. Good quality product. Vertical mills produce high quality products due to their smooth surface finish.

How much does it cost to purchase and install spodumene lepidolite vertical mill?

The cost to buy and install a spodumene lepidolite vertical roller mill can range from a few thousand dollars to tens of thousands of dollars, depending on the model and location. The price also depends on the quality of the mill, with high-quality mills costing more than low-quality mills.

SMMVIK Machinery manufacturers of spodumene lepidolite vertical mills are in high demand due to the high quality of their products and the competitive prices they offer. The mills can be used to produce a variety of primary and secondary materials, including calcium carbonate, titanium dioxide, and barium sulfate.

The mills typically use three rollers to break down the rock into small pieces that can be easily processed by other machinery. The rolling process also helps to release the minerals from the rock, making it easier for them to be extracted. This makes spodumene lepidolite vertical roller mills one of the most efficient ways to extract these minerals.

If you are looking for a reliable manufacturer of spodumene lepidolite vertical grinding machine, you should definitely consider SMMVIK Machinery. We ensure that all our products are of the highest quality and meet your various requirements, which is why we become one of the most popular suppliers in this field. You are welcome to consult, learn more about our products and we can configure appropriate equipment for you according to your budget and needs to maximize your benefits.