The mineral spodumene Lepidolite is a dark green, black, or brown mineral that has a Mohs hardness of 6 to 6.5 and a specific gravity of 2.7 to 3.2. It is found in association with other minerals such as ilmenite, and can also be found as an isolated mineral. Spodumene Lepidolite is usually produced as a byproduct of the lepidolite ore processing process.

Spodumene Lepidolite is used primarily for jewelry making and decorative purposes. It is also used in polishing and abrasive products. Spodumene Lepidolite is a mineral that is found in many places on Earth, but is most common in the United States. It is often used as an ornamental stone and as a gemstone. Spodumene Lepidolite can also be used for jewelry, and it can be used to make clocks and watches.

The lepidolite ore is found in the United States, Mexico and Brazil. The mineral is crushed and processed into spodumene Lepidolite which is used in jewelry, gemstones and other decorative objects. A crusher is typically used to reduce the size of the Spodumene Lepidolite. This is done by breaking it down into smaller pieces so that it can be more easily transported and sold.

There are many different applications for spodumene lepidolite crushers in the United States. Some of these applications include mining, manufacturing, and energy production. Mining is the most common use for spodumene lepidolite crushers in the United States. Spodumene lepidolite is a type of ore that is often found near mines.

These mines can be used to extract spodumene lepidolite from the ground. Manufacturers also use spodumene lepidolite crushers to produce various products. One example of this is jewelry manufacturing. Energy production is another popular application for spodumene lepidolite crushers in the United States. This is because spodumene lepidolite can be used to create fuel pellets or other products.

How is spodumene lepidolite mined? Manufacturing process of spodumene lepidolite crushers.

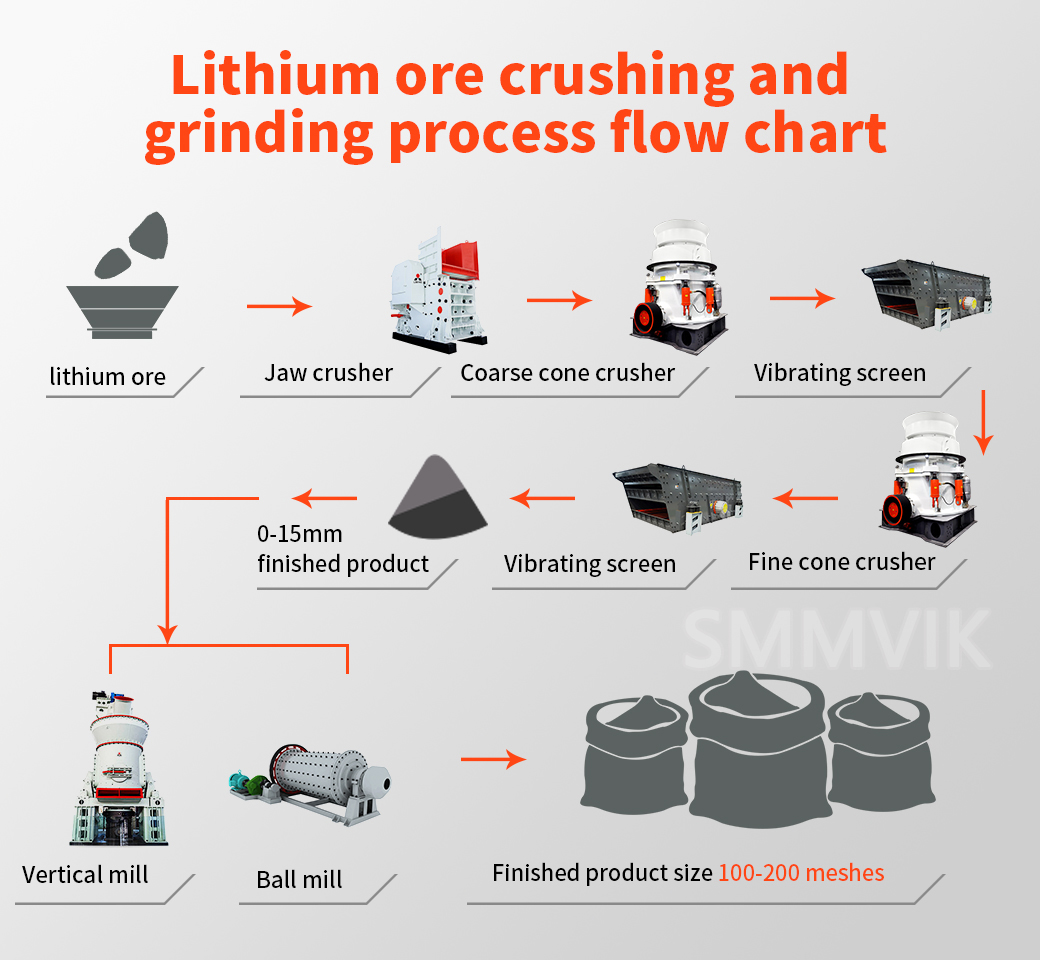

The mining of spodumene lepidolite is a very labor-intensive process. First, the ore is crushed using heavy equipment to release the mineraloids. These are then separated by size and passed through a series of filters to remove any large pieces of rock. After this, the minerals are loaded onto trucks and taken to a processing plant. Here, they are heated until they reach a high enough temperature to melt. The liquid spodumene is then poured into molds and allowed to cool. This produces small pieces of spodumene lepidolite that can be sold on the market or used in manufacturing processes.

In the manufacturing process of spodumene lepidolite crushers, lumps of spodumene are first crushed into smaller pieces using a hammer and anvil. The small pieces are then heated until the rocks turn into a liquid form. Next, the liquid rocks are poured into a funnel and funneled down a pipe into a machine called a hydrocyclone. The hydrocyclone removes any large chunks of rock from the liquid form and leaves the spodumene lepidolite in tiny pieces that can be easily processed.

What are the different types of crushers used for spodumene lepidolite?

There are a few different types of crushers used for spodumene lepidolite. These include jaw crushers and cone Crushers.

Jaw Crushers: Jaw crushers are the most common type of crusher used for spodumene lepidolite. They use a metal jaw to crush the rock into small pieces.

Cone Crushers: Cone crushers are similar to jaw crushers, but they have a flat surface on the bottom instead of a metal jaw. This makes it easier to crush the rock into smaller pieces.

The price of spodumene lepidolite crushers can vary depending on the type and quality of the machine. The most common types are primary, secondary and tertiary crushers. Primary crushers cost less than secondary crushers but more than tertiary crushers. Secondary crushers are the most expensive option and are used to reduce the size of the ore before it is sent to a tertiary crusher.