What is the production process of lithium carbonate? How to select lithium ore mill? Lithium carbonate is the raw material of lithium battery, which is extracted from solid lithium ores such as spodumene and lepidolite. With the development of new energy industry and lithium battery technology, the demand for lithium is increasing, which is widely used in new energy vehicles and other fields.

Lithium carbonate production process refers to the process of extracting lithium resources from lithium minerals such as spodumene and lepidolite. The main production processes include lime sintering method and sulfuric acid method, of which sulfuric acid method is the main method currently used.

Lithium extraction from spodumene - sulfuric acid method:

Generally, the process includes conversion roasting, sulfation roasting, clinker leaching and washing, purification of leaching, evaporation and concentration of purified solution, lithium precipitation, sodium sulfate, etc.

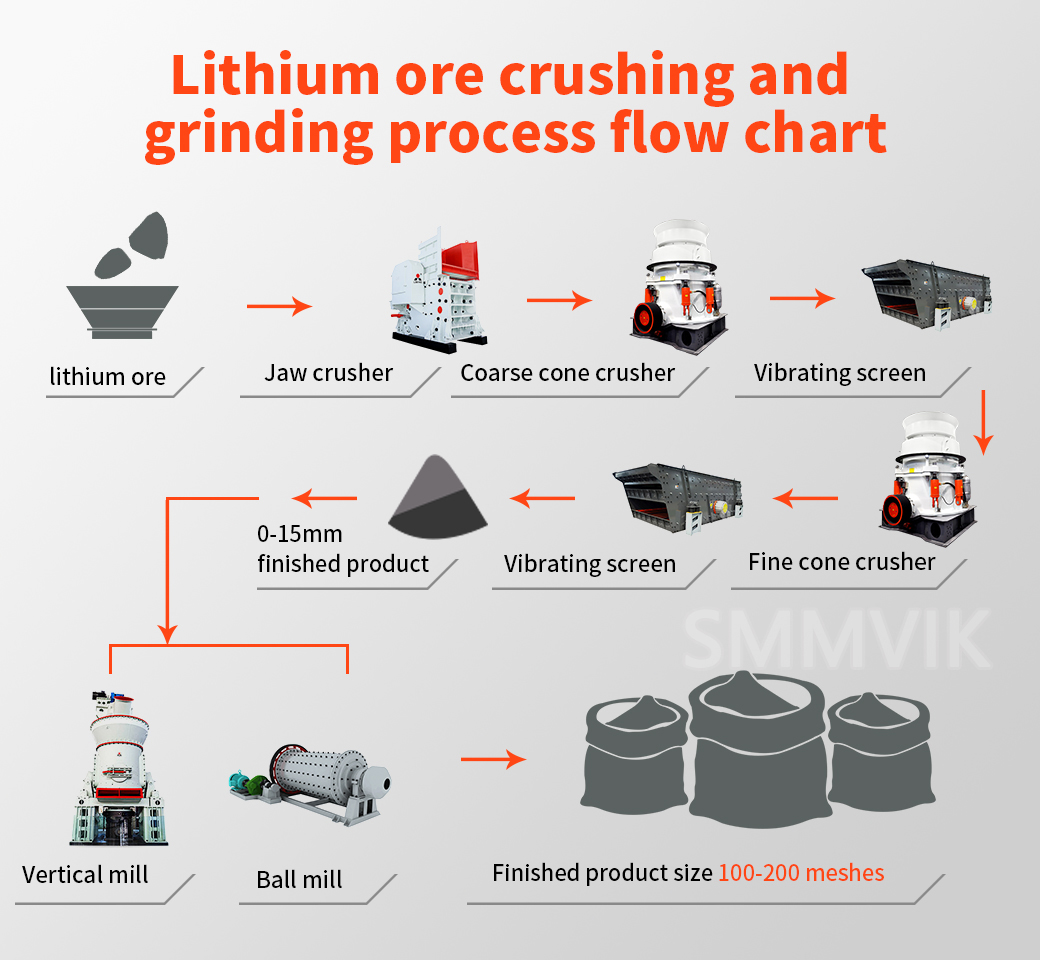

Whether extracting lithium by sulfuric acid or sintering, the crushing of spodumene and lepidolite ores and the grinding of calcined materials are at the front of the process flow.

For the problem of raw ore crushing of spodumene and lepidolite, jaw crusher and cone crusher can be selected to crush the raw ore to less than 1cm to prepare for the next stage of grinding feeding.

In view of the problem of how to select a lithium ore mill, it is recommended to select a vertical mill equipped with high temperature resistant materials and hot air system because of the high grinding temperature of spodumene and lepidolite after high temperature roasting.

In addition, the vertical mill integrates crushing, drying, grinding, grading and conveying. It has powerful functions, and its output is relatively large among the mills. The single machine hourly output can reach 6-80 tons, which can meet the deep processing and extraction of large-scale lithium resources.