Mineral processing is a business that has seen a lot of advances in recent years. This is due in part to the growth of the mining and mineral industry, but also to the development of new technologies. One such technology is spodumene lepidolite vertical roller mills, which have revolutionized the way minerals are processed.

As you may know, spodumene lepidolite is a rare mineral that is used for a variety of purposes, including jewelry, electronic components, and paint. Vertical mill is a particularly effective method to extract this mineral from ore. Because of this, vertical mill has become very popular in recent years. If you want to get into the mineral processing business, spodumene lepidolite vertical mills are a key technology that you need to know about.

What is spodumene lepidolite? Spodumene lepidolite is a type of rare mineral that has been used as a gemstone and as a abrasive. It is also used in the production of optical glass. Spodumene lepidolite is a mineral that is found in some of the most remote places on Earth. It can be found in South America, Africa, and Asia. Vertical roller mills are used to grind various materials into small pieces. Spodumene lepidolite is used to grind materials such as coal, ore, and other minerals into small pieces so they can be processed by other machines.

Spodumene lepidolite is a type of hard mineral that contains lithium and can occur in the form of crystals or as a powder. The mineral is used to make jewelry, tools, and other objects. One of the properties of spodumene lepidolite that makes it useful for objects such as jewelry is its hardness. Spodumene lepidolite is one of the hardest minerals on Earth, making it resistant to scratches and other types of damage. This property makes it ideal for use in products such as watches and glasses.

Another advantage of spodumene lepidolite is its color. Many different colors are available, allowing for a wide range of designs to be created with jewelry made from the mineral. One final property of spodumene lepidolite that is worth mentioning is its heat resistance. Because the mineral contains lithium, it can withstand high levels of heat without damage. This makes it perfect for use in areas such as cooking pans and ovens.

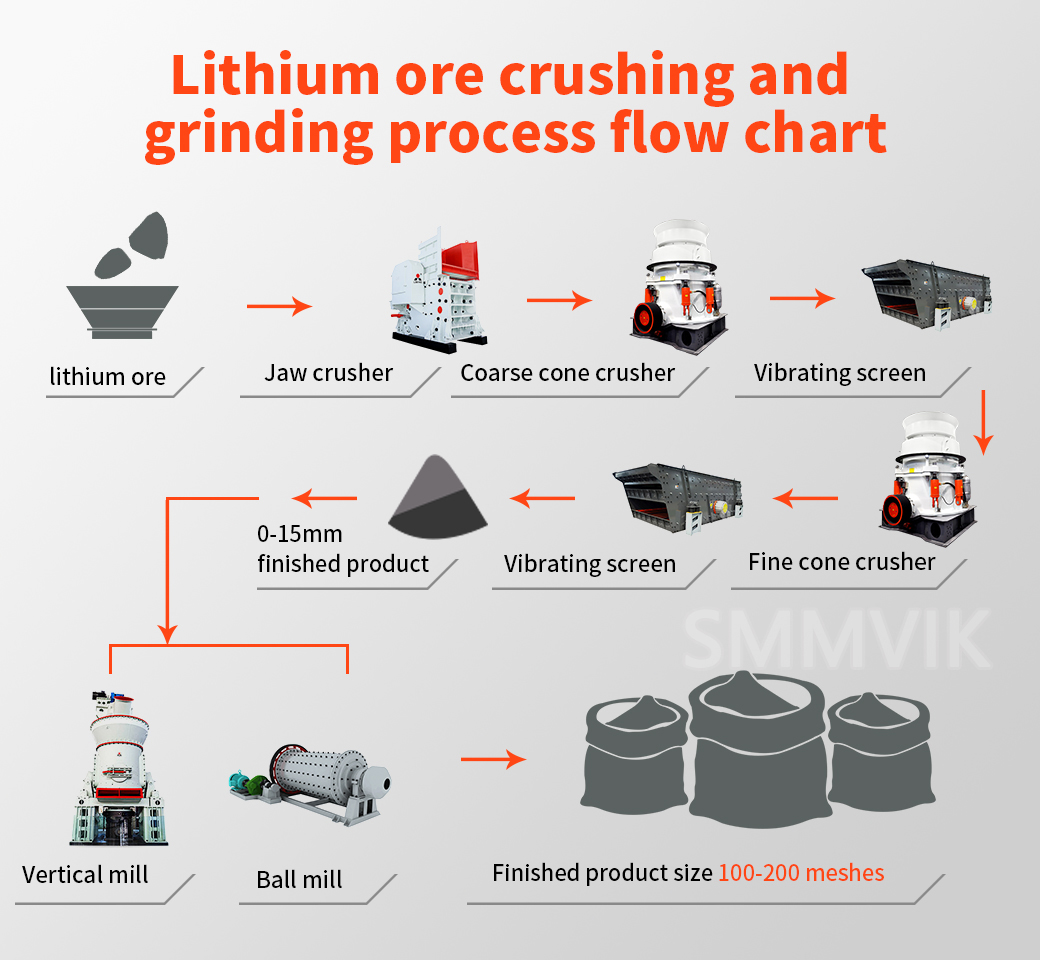

In the mining and manufacturing industries, vertical roller mills are widely used due to their high capacity, low speed, and easy operation. They are also commonly used in the production of certain types of minerals, such as spodumene lepidolite. Mills can be classified according to the type of material being ground: ball mills or vertical mills. Ball mills are best suited for grinding materials that have a hard texture, such as powdery metals or stones.

Vertical roller mills can be used to produce several different types of mineral products. Spodumene lepidolite is one of the most common minerals processed using a vertical roller mill. This mineral is found in deposits all over the world and is used in various applications, including solar panels and lithium-ion batteries.

Using a vertical mill to process spodumene lepidolite results in a more consistent product with fewer impurities than methods that use other types of machinery. The high speed and large capacity of this type of mill mean it can handle large amounts of material quickly and efficiently.

A spodumene lepidolite vertical mill is a type of crushing plant that uses vertical rollers to break down the rock into smaller pieces. The benefits of using a spodumene lepidolite vertical mill include:

1. The mill can handle a wide range of materials, from sand to rocks and minerals.

2. The process is relatively quick and efficient, making it an ideal choice for large-scale mining or processing operations.

3. The plant is also suitable for use in harsh environments, thanks to its robust construction and Abilities to function in high-pressure and low-temperature conditions.