Spodumene lepidolite is a type of gemstone that's prized for its unique color and clarity. It's also been used in jewelry and other decorative objects for centuries. However, the demand for spodumene lepidolite has skyrocketed in recent years, which has led to a shortage of the mineral.

In this post, we will explore the factors that have led to the shortage of spodumene lepidolite and how you can help solve the problem. We will also provide tips on how to find a manufacturer of spodumene lepidolite grinding machine.

The mineral spodumene lepidolite is a light-colored, brittle mineral that is found in Lepidolite group of minerals. Spodumene lepidolite is the most common and valuable member of this group. It is colorless, transparent, and has a Mohs hardness of 5 to 6.

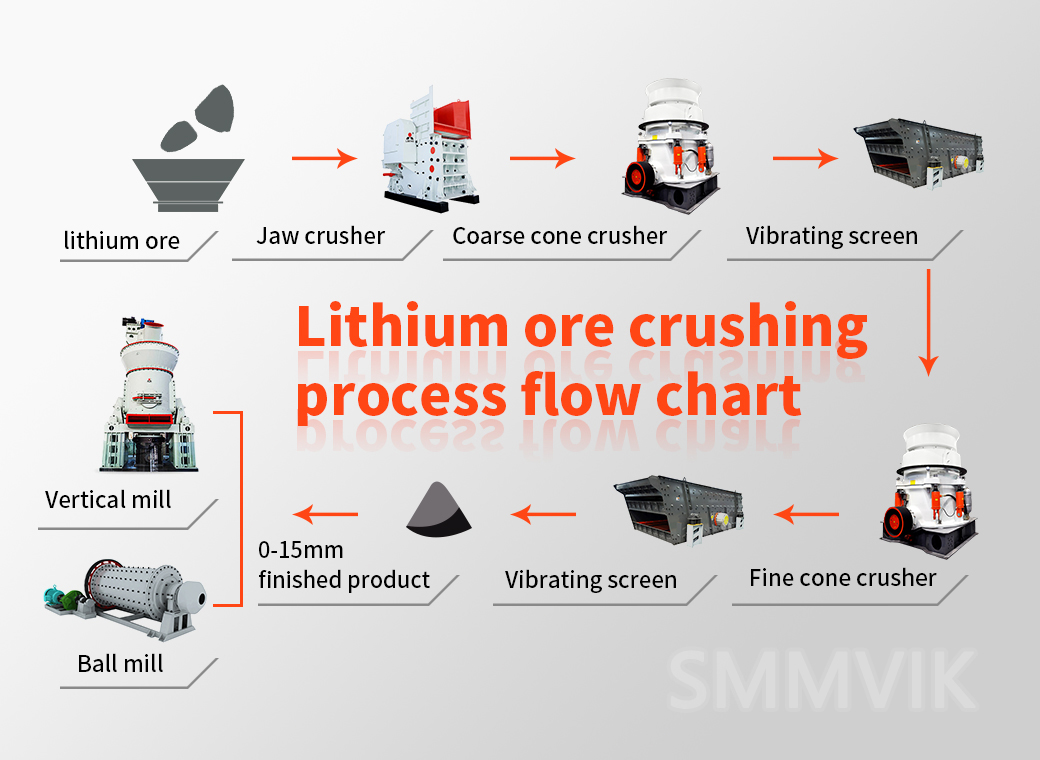

Spodumene lepidolite is extracted from the earth by various mining processes such as open-pit mining, underground mining, and quarrying. The mining process depends on the availability of the spodumene lepidolite deposit. The raw material is then processed into different products such as flake, powder, granules, and blocks.

The most common method to extract spodumene lepidolite from the earth is by open-pit mining. This type of mining involves removing the overburden using explosives or bulldozers before extracting the desired minerals using a bucket truck or an underground mine cart. The overburden can be very heavy, making this type of mining difficult and time-consuming.

Another method for extracting spodumene lepidolite from the earth is by underground mining. This type of mining involves drilling down into the ground until you reach the desired deposit location. Then, you remove the overburden using explosives or drills before extracting the desired minerals using a bucket truck or an underground mine cart. Underground mines are less damaging to environment than open-pit mines because they do not expose the ground to the air and sunlight.

The final method for extracting spodumene lepidolite from the earth is by quarrying. This type of mining involves removing the overburden using a machine such as a bulldozer or an excavator before extracting the desired minerals. Quarrying is less damaging to environment than open-pit mining and underground mining because it does not involve removing the overburden.

What are the different grades of spodumene?

There are different grades of spodumene depending on the quality and purity of the mineral. The most common grades are Type I, Type II, and Type III. The three types of spodumene are distinguished by their crystal structure and optical properties.

Type I spodumene is made up of small crystals that have a rhombohedral shape. It has a yellow to orange color and is the most common type of spodumene.

Type II spodumene is made up of larger crystals that have a hexagonal shape. It has a blue color and is less common than type I spodumene.

Type III spodumene is made up of even larger crystals that have a cubic shape. It has a purple color and is the rarest type of spodumene.

There are various types of grinding machines used to grind spodumene lepidolite, including raymond mill, vertical mill, and ball mill.

Raymond Mill is a horizontal type mill that is widely used to grind various minerals. It has the advantage of high efficiency and low cost.

Vertical mill is mainly used for grinding medium size ores. It has the advantages of high output and low energy consumption.

The ball milling process is the most complex and labor-intensive of the three methods because it uses rotating balls to crush the gemstone.

If you are looking for a reliable manufacturer of spodumene lepidolite grinding machine, you should consider SMMVIK Machinery. SMMVIK Machinery has years of experience in the mining and manufacturing industries, which gives them an advantage when it comes to producing high-quality machines. Not only do they have the ability to produce high volumes, but they also have the expertise necessary to create machines that meet your specific needs.