Spodumene lepidolite is a rare mineral that is found. The mineral is usually found as granules or pellets and can be used to produce gemstones. It is also used to make jewelry and other objects. The mining of the mineral has caused environmental problems in the past, but it is now being mined more carefully.

The spodumene lepidolite, also known as ilmenite, is a type of mineral that is considered to be one of the most valuable and rare earth minerals on the planet. It is found in various parts of the world, but is especially abundant in South America.

Spodumene lepidolite has several important properties that make it a desirable mineral. Among these are its high purity levels, which make it a good choice for components in electronic devices and other technological products, its resistance to corrosion, and its ability to form hard crystals that are able to withstand great amounts of stress.

The production of spodumene lepidolite crushers is of high importance as this mineral is used in a number of industries such as the automotive, aerospace and telecommunications sectors. The global demand for spodumene lepidolite crushers is increasing yearly due to the growing popularity of this mineral in the global market.

Spodumene lepidolite is a type of ore that is found in some South American countries. The mining process for spodumene lepidolite involves extracting the ore from the ground using various methods. Once the ore has been mined, it must be processed before it can be turned into usable products.

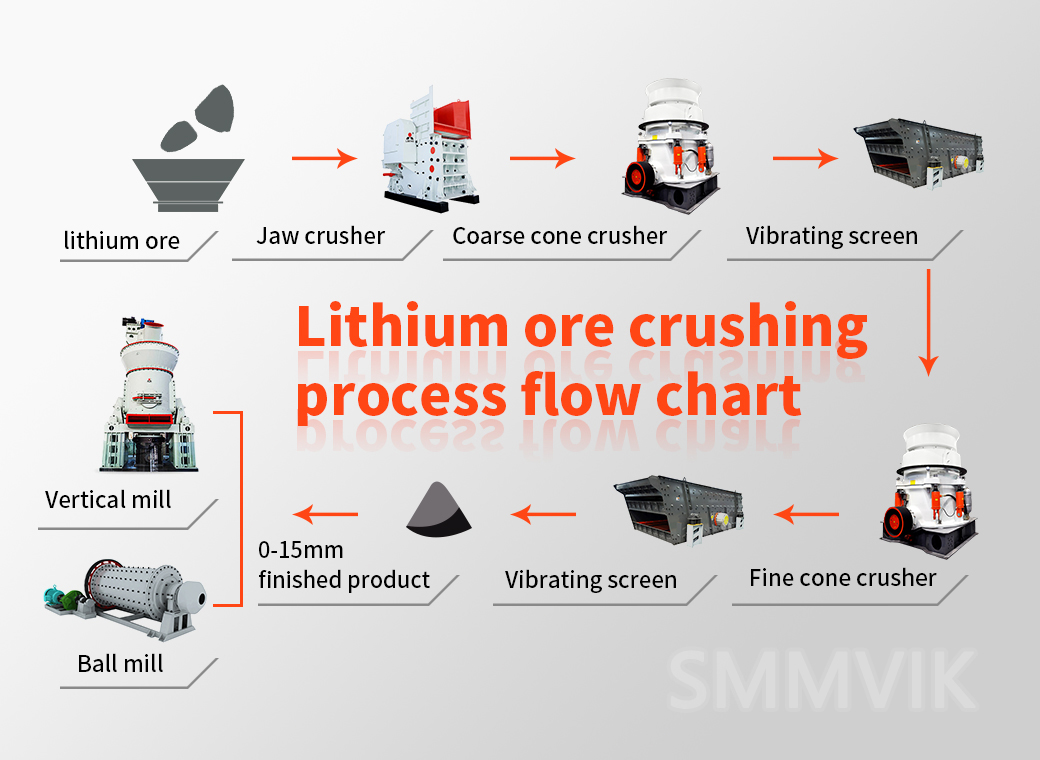

The mining of spodumene lepidolite is a very difficult process that requires a lot of hard work and patience. The lepidolite is first extracted from the ground using a number of different methods, including open-pit mining and underground mines. Once the lepidolite has been extracted, it must then be processed in order to make it into usable form. This process can involve a number of different steps, including crushing and grinding. After the lepidolite has been processed, it must be shipped off to a manufacturing facility where it will be turned into various products.

The first step in processing spodumene lepidolite is to extract the mineral using a crusher. The crusher will break down the rock into smaller pieces, which will allow it to be more easily processed. After the mineral has been extracted, it must be cleaned and processed further before it can be used in products. Cleaning involves removing any impurities that may have been included in the mineral during extraction. Processing further involves shaping and cutting the mineral into specific shapes, which will enable it to be used in products.

Crusher manufacturers offer two main types of crusher designs for spodumene lepidolite: jaw crushers and impact Crushers. Jaw crushers are more common because they are cheaper to operate. They use horizontal motion to break the rock into smaller pieces. Impact Crushers are more expensive to operate but can produce larger chunks of material.

The cost of spodumene lepidolite crusher depends on the type and quality of the machine. As the price level increases, these machines will add more functions, such as higher crushing capacity and longer service life. It should be noted that not all of these crushers have warranty or technical support. Therefore, when selecting equipment, try to choose one with after-sales maintenance to save a series of subsequent maintenance costs.