When you're looking for a high quality spodumene lepidolite crushing machines, it's important to look for a supplier who can offer you the best possible service. After all, you don't want to end up with a machine that's not up to your standards. In this article, we will discuss some of the things to keep in mind when searching for a spodumene lepidolite crushing machines supplier. From quality assurance to customer service, read on to learn everything you need to know about finding the right supplier for your needs.

Spodumene lepidolite is a type of hard mineral that is mostly found in South America. It is used in jewelry and other decorative objects. There are many different ways to crush spodumene lepidolite, but the most common way to do it is using a crusher.

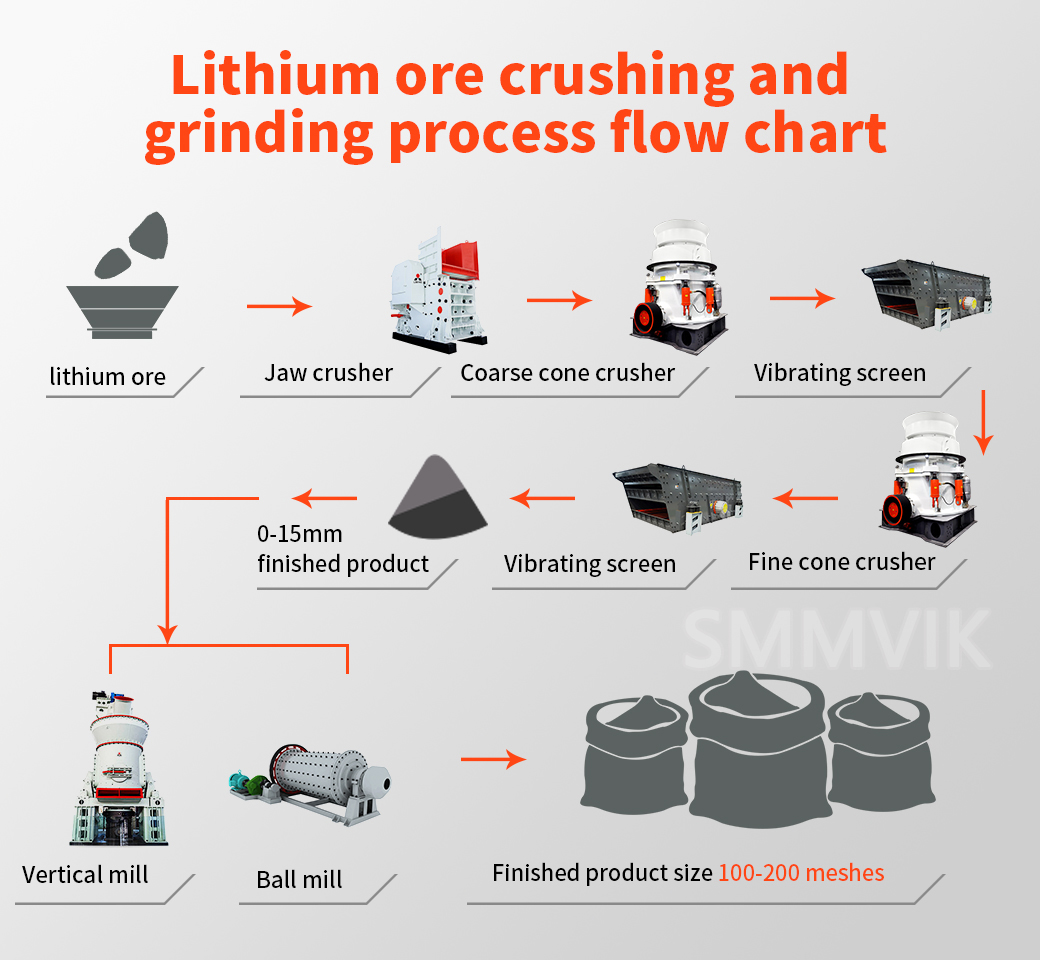

There are three main types of crushing machines used for processing spodumene lepidolite: impact crusher, ball mill, and jaw crusher. Impact crushers use a concussive force to break the mineral down into smaller pieces. Ball mills use a rotating sphere to crush the mineral. Jaw Crushers use a movable jaw to crush the mineral between two grinding surfaces.

There is a great demand for spodumene lepidolite crushing machines in the global market. The following are some of the reasons why this mineral is in high demand:

1. Spodumene lepidolite has unique physical and chemical properties that make it an excellent choice for use in applications such as jewelry, tools, and other equipment.

2. It is a very dense gemstone that can be easily processed into various forms and sizes.

3. Its price is relatively low when compared to other gems, making it a good choice for small-scale producers and individuals who want to invest in mining operations.

If you are interested in crushing spodumene lepidolite rocks, there are some things you will have to consider. Spodumene lepidolite is a valuable mineral that can be used for jewelry making, fossil fuels, and other industrial purposes. However, because it is so hard and brittle, it is difficult to break into smaller pieces without damaging the rock.

The first step in crushing spodumene lepidolite is to determine the size of the rock you want to break down. For small pieces that will not need to be processed into very fine particles, a hammer or chisel can be used. For larger pieces that will need to be broken down into smaller pieces, a crusher or grinder may be more appropriate.

Once you have determined the type of machine needed, the next step is to choose the right one for the job. There are several different types of crushers and grinders available on the market today, each with its own advantages and disadvantages. Before buying a machine, it is important to test it out by using a small sample of your desired rock material. This will help ensure that the machine chosen is capable of breaking down your material properly.

After choosing the right machine and testing it out, the final step in crushing spodumene lepidolite rocks is loading it up and getting started. Depending on the type of machine being used, processing time may vary from minutes to hours. Once processing is complete, the crushed rock can be separated into smaller pieces using a crusher or grinder.

As a leading spodumene lepidolite crushing machines supplier, we understand the importance of delivering high-quality equipment to our customers. Our machines are designed for maximum efficiency, and they can handle a wide range of materials with ease. Plus, our experts are always available to help you get the most out of your equipment, so you can achieve optimal results every time. If you have any questions or concerns about our equipment, don't hesitate to reach out to us at any time.