Introduction to spodumene mill. What can spodumene powder do? Spodumene belongs to monoclinic system, and the crystal is usually columnar, granular or tabular. The color is gray white, gray green, purple or yellow, the hardness is 6.5-7, and the density is 3.03-3.22g/cm3. As the raw material of lithium chemicals, it is widely used in lithium chemical industry, glass and ceramic industry.

As an industrial ore that is the main source of lithium group, spodumene is widely used in ceramics, metallurgy, porcelain removal, special glass, chemical industry and other fields, and its application in new energy vehicles is also widely concerned.

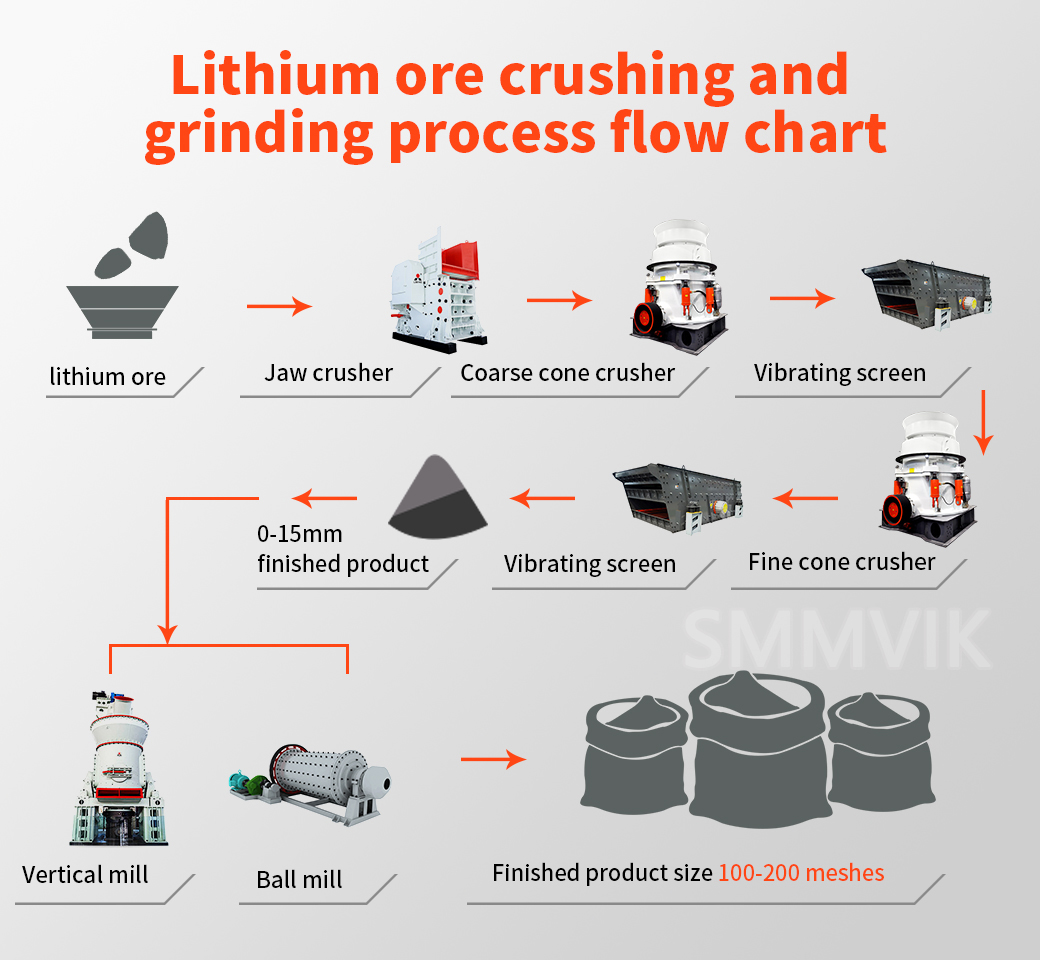

For the application of spodumene in the above fields, it is first necessary to grind spodumene into fine powder, and the grinder plays an important role in the middle.

For new energy vehicles and other applications, the processing fineness of spodumene is generally 200 meshes, and the MTW European version mill and LM vertical mill of SMMVIK Machinery can meet their processing needs.

MTW European version mill: The fifth generation of upgraded Raymond mill is a national patented product developed by our company on the basis of absorbing European grinding technology and concept. This model uses a number of new patented technologies such as bevel gear integral transmission, internal thin oil lubrication system, arc air duct, etc. It is an ideal replacement for the upgrading of traditional Raymond mill and pendulum mill.

The feed size is 30-50mm, the discharge size is 80-425 mesh, and the output can reach 3 - 50T/H.

LM vertical mill: SMMVIK Machinery has actively learned from foreign successful experience and launched products with independent intellectual property rights through continuous technological innovation and upgrading of the R&D team. This equipment is widely used in cement, power, metallurgy, chemical industry and other industries, and focuses on three major fields: non-metallic ore, coal powder and slag. It is more suitable for large-scale production of mineral powder.

The feeding size is 38-65mm, the discharging size is 80-425 mesh, and the output can reach 6 - 70T/H.

It can be selected according to the actual production demand. Generally speaking, the investment amount of the vertical mill system is higher than that of the European version. You can tell your output, budget and other needs to our customer service staff, we will let the professional technical staff for you to develop the appropriate choice of your plan and quotation budget, for your reference.