Hardness is one of the most important properties of a material. It affects how a material behaves under stress, and can determine its physical and chemical properties. Without knowing the hardness capactiy of a particular material, it's difficult to engineer products that are appropriate for that material.

In this post, we will discuss the hardness capactiy of crushers for spodumene lepidolite. By understanding how hard this rock is and which crusher is best suited for it, you can ensure that your products are compliant with all relevant safety and quality standards.

Spodumene Lepidolite is a mineral found in deposits world-wide. It's color ranges from a light yellow to a deep green, but most specimens are shades of yellow and green. The hardness of spodumene lepidolite is 6.5 on the Mohs scale, making it much softer than other minerals found in the same geological setting. This softness makes it an ideal material for crushers because it doesn't damage the crusher teeth and produces very small pieces that can be easily processed.

A crusher's maximum hardness capability is determined by its crushing capacity. The higher the crushing capacity, the higher the hardness of the final product. A crusher's maximum hardness capability is also determined by its wear head and jaw depth.

A crusher is one of the primary types of crushers used in the mining and ore processing industries. There are different types of crushers, each with its own unique features and capabilities. How to Choose the Right Crusher for Spodumene Lepidolite?

There are a few things to consider when choosing the right crusher for spodumene lepidolite. The hardness capactiy of the crusher is one factor to consider. The other factors include the type of feed, the crusher's discharge capacity, and the size of the output cone.

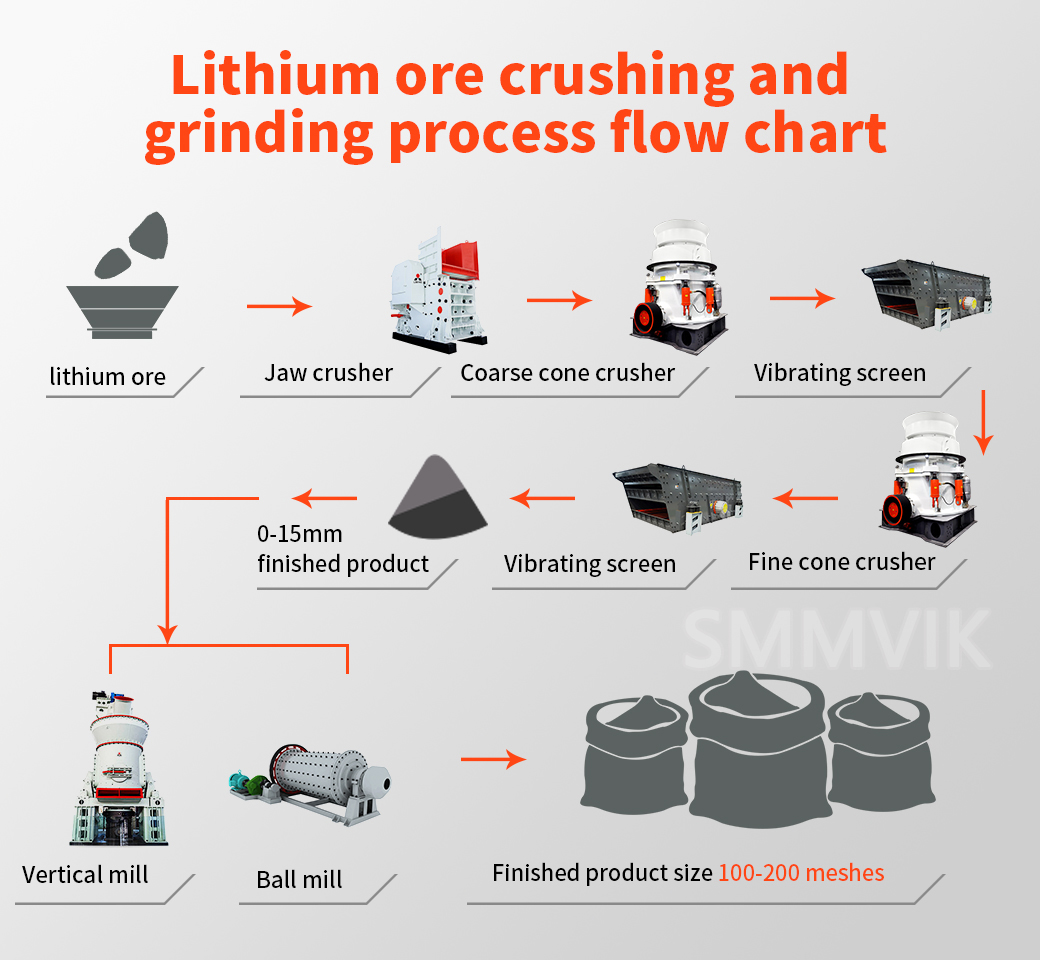

There are different types of crushers for spodumene lepidolite, and each has its own advantages and disadvantages. The most common type of crusher is the jaw crusher, which uses a heavy metal jaw to crush the rock. Jaw crushers are good for relatively small rocks, but they can't handle very large rocks.

The impact crusher is similar to the jaw crusher, but it uses an impactor to break the rocks into smaller pieces. Impact crushers are good for medium-sized rocks and can handle larger rocks if they're broken into smaller pieces.

The ball mill is probably the best choice for large amounts of spodumene lepidolite. Ball mills use a rotating cylinder filled with crushed rock to grind the spodumene lepidolite down into smaller pieces. Ball mills are slow compared to other types of crushers, but they're extremely efficient at grinding down large amounts of material quickly.

If you want to choose a suitable crusher, you are welcome to consult. SMMVIK Machinery has many years of experience in R&D and production, and is a reliable manufacturer. We can choose the appropriate equipment for you according to the user's output, broken materials, budget and other needs. We look forward to your arrival.