Spodumene lepidolite is one of the most important ore minerals in the world. It is a silicate mineral that is found in many places around the world, including South America. The mineral is used in a variety of industries, including aluminum production and battery manufacturing. The spodumene lepidolite mining crushing production line in south america is a vital part of this mineral's production. It is used to break down the rock into smaller pieces so that it can be more easily extracted and processed. In this post, we will explore the details of this production line and how it works.

South America is the top mineral mining region in the world. Over 50% of all the spodumene lepidolite mined each year is from South America. The crush production line for this mineral is typically located in south america because it is a non-metallic mineral with low value, making it less labor intensive to produce.

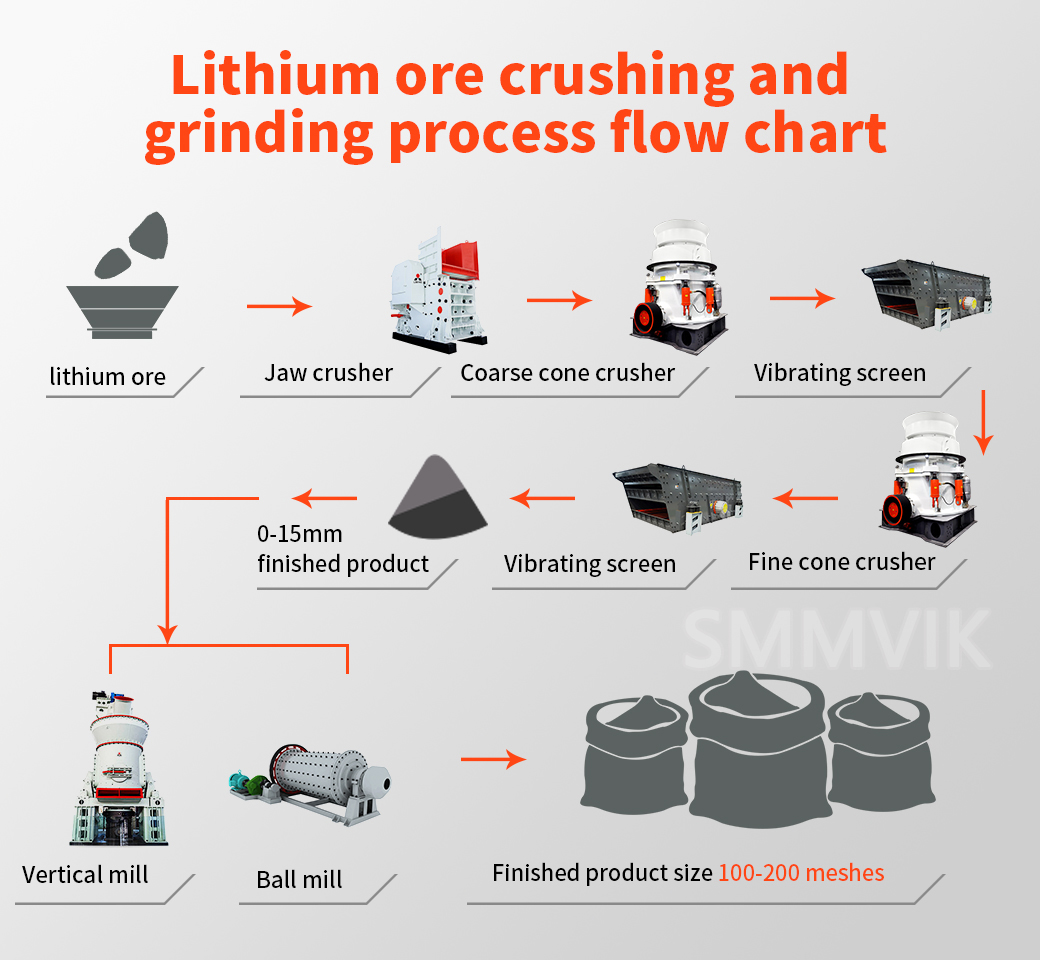

The production line for spodumene lepidolite mining starts by extracting the ore from the ground. This can be done using a number of different methods, including open-pit mining and underground mining. After the ore has been extracted, it must be processed before it can be used. This process includes crushing the ore to create small pieces that are easier to transport and process. Then, the pieces must be heated to make them less brittle so they can be shaped into products such as rods or discs.

The spodumene lepidolite mining crushing production line is mainly used to extract the gem mineral spodumene from the earth. The production line includes a number of crushers, grinders. The process begins by loading the ore into the crushers, which break it down into smaller pieces. The smaller pieces are then transferred to the grinders, where they are ground into a fine powder. The powder is then moved through a series of filters before being sent to the vaporizing unit, where it is turned into a gas and heated up until it becomes a liquid. This liquid is then drawn off and condensed back into a solid form, which is called spodumene lepidolite.

The production process for spodumene lepidolite mining is complex and depends on the type of mine being exploited. In open-pit mines, the ore is extracted by crushing the rock with heavy equipment. Once the ore is crushed, it is transported to a processing plant where it is washed and processed. Spodumene lepidolite can be mined in many different ways, but all involve some form of crushing.

The primary benefit of spodumene lepidolite mining is the large amount of high-quality gemstones that can be recovered. The crushed rock produced from the mining process is a good quality fertilizer and construction material, providing many benefits to the environment. Additionally, the economic value of spodumene lepidolite is increasing, making it an increasingly attractive resource for miners.

There are many potential environmental risks associated with spodumene lepidolite mining. Spodumene is a mineral that can be mined using a number of different production methods, including open-pit and underground mining.

Open-pit mining is the most common type of spodumene lepidolite mining and involves removing the rock from the ground by breaking it down with heavy equipment. This method can lead to environmental issues such as soil erosion and contamination of water supplies. Underground mining is another type of spodumene lepidolite mining that uses tunnels to extract the mineral from the ground. This method is less likely to cause environmental damage, but it can be more expensive than open-pit mining.

Another potential environmental risk associated with spodumene lepidolite mining is exposure to mine workers. Mine workers may be exposed to harmful chemicals while working in the mines, which could lead to health problems.

What are the mining and processing costs of spodumene lepidolite?

There are a few things that need to be taken into account when considering the mining and processing costs of spodumene lepidolite. The first is the grade of ore that is being mined. Higher quality ores will require more processing and thus cost more to extract. Secondly, the size and shape of the spodumene lepidolite crystals will also affect the cost of extraction.

Crystals that are larger and have an irregular shape will require more time and energy to process than smaller, rounder crystals. Finally, transportation costs are also a consideration when calculating mining and processing costs. Large deposits of spodumene lepidolite may be located remote from major mining communities, which would increase transportation costs associated with getting the ore to market.