Lithium-ion batteries have revolutionized the way we use technology. They're small, light, and powerful, and they have completely reshaped the way we think about energy storage. But where does the lithium come from? Most of it comes from a mineral called spodumene lepidolite. In this article, we will explore the crushing and grinding process that is used to extract this mineral from the ground.

What is spodumene lepidolite?

The lepidolite mineral spodumene is a valuable resource for the manufacture of lithium ion batteries. Spodumene lepidolite is a hard, strong mineral that requires special processing to be turned into a usable battery material.

The lithium ion battery industry is experiencing rapid growth, as electric vehicles and renewable energy systems become more popular. The most common source of lithium is spodumene lepidolite, which is a soft, blue-green mineral that occurs in many parts of the world.

Spodumene lepidolite can be crushed and ground into a fine powder to make lithium cells. The required amount of spodumene lepidolite depends on the type of lithium cell being manufactured. For example, a small cell requires less than 1% spodumene lepidolite, while a large cell may require up to 25%.

How to mine spodumene lepidolite ore?

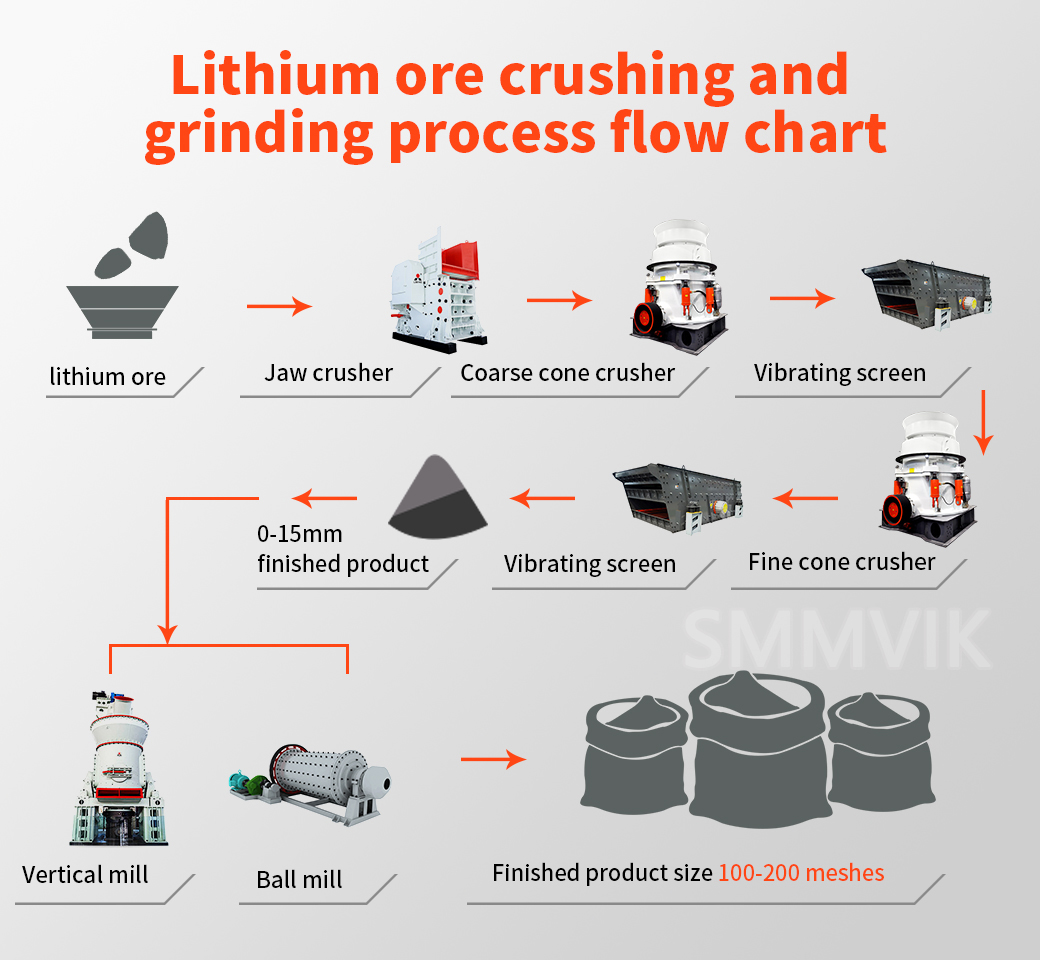

The first step in the mining process is to locate and identify the lepidolite deposit. Once the deposit has been identified, mining crews begin drilling into it to extract the ore. After the ore has been extracted, it must be processed before it can be used in batteries. The initial step in this processing is crushing the ore to obtain smaller pieces that can be more easily moved and processed.

Second, grinding operations are used to smooth out the texture of the ore so that it can more easily absorb chemicals during battery manufacturing. Finally, acid washing is performed to remove any impurities from the ore. All of these steps are necessary for producing high-quality lithium ion batteries from spodumene lepidolite deposits. By properly processing and extracting this mineral, companies can create products that have a long lifespan and are environmentally friendly.

The production of lithium cells from spodumene lepidolite can be accomplished by a number of different methods. The most common method is to crush the lepidolite and then grind it into a fine powder. This process allows for the extraction of lithium from the lepidolite. A second method is to heat the lepidolite until it melts, and then extract the lithium using a solvent.

The crushing process of spodumene lepidolite for manufacturing lithium cell involves the use of heavy machinery to reduce the rock into small pieces. The crushed rock is then screened to remove any large pieces, and the smaller rocks are then ground into a powder. The grinding process of spodumene lepidolite is used to produce lithium ion cells. The mineral is crushed into very small pieces and then ground down into a fine powder. This process allows for the production of high quality lithium ion cells.

In recent years, the crushing and grinding of spodumene lepidolite for manufacturing lithium cell has become a popular process. Spodumene lepidolite is an important ore mineral that is used to produce high-quality lithium cells. The crushed and grindspodumene lepidolite undergoes a series of processes, including milling, ball milling, classifying and flotation to extract the lithium content.