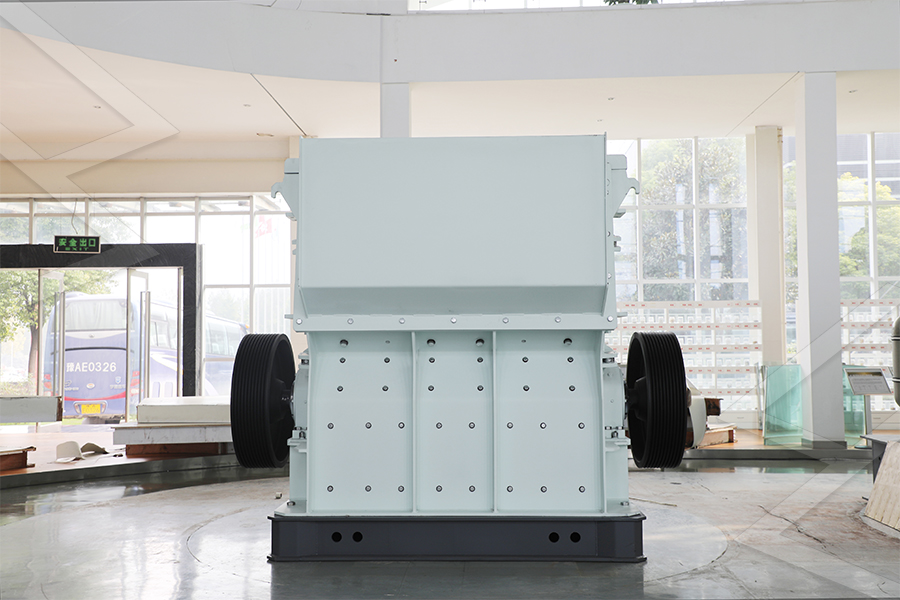

Jaw crusher can produce granite, dolomite, bluestone, quartzite, iron ore and other stones with a compressive strength of no more than 320. The processed finished product has a uniform grain shape, which is favored by many users.

How to maintain the production capacity of jaw crusher?

1. Control environment variables: When it running, pay attention to the temperature of the motor they are equipped with. If the temperature is too high, it will damage the motor;

2. Feeding uniform amount and constant speed: Continuous feeding at the same amount and speed will maintain the healthy operation of the machine and greatly promote its work efficiency;

3. The belt tension is appropriate: To maintain the appropriate transmission belt tension, do a good job in the drive maintenance, to avoid belt slippage, speed reduction, etc., can help increase the production capacity, while reducing energy consumption.

4. Operate the equipment correctly: To ensure that the equipment can produce "continuous output" with high output, the operator must ensure that the equipment is accurately controlled, as far as possible to guide the feeding point to the center of the machine's inlet, which can improve efficiency.

How to maintain the production capacity of jaw crusher?

1. Control environment variables: When it running, pay attention to the temperature of the motor they are equipped with. If the temperature is too high, it will damage the motor;

2. Feeding uniform amount and constant speed: Continuous feeding at the same amount and speed will maintain the healthy operation of the machine and greatly promote its work efficiency;

3. The belt tension is appropriate: To maintain the appropriate transmission belt tension, do a good job in the drive maintenance, to avoid belt slippage, speed reduction, etc., can help increase the production capacity, while reducing energy consumption.

4. Operate the equipment correctly: To ensure that the equipment can produce "continuous output" with high output, the operator must ensure that the equipment is accurately controlled, as far as possible to guide the feeding point to the center of the machine's inlet, which can improve efficiency.